In the world of commercial construction, efficiency, precision, and cost-effectiveness are paramount. As projects grow in size and complexity, contractors increasingly rely on advanced technologies to streamline operations. One such technology is concrete pumping, which has revolutionized the way concrete is delivered and placed at construction sites. This method plays a pivotal role in ensuring that large-scale commercial construction projects are completed on time, within budget, and with superior quality.

What is Concrete Pumping?

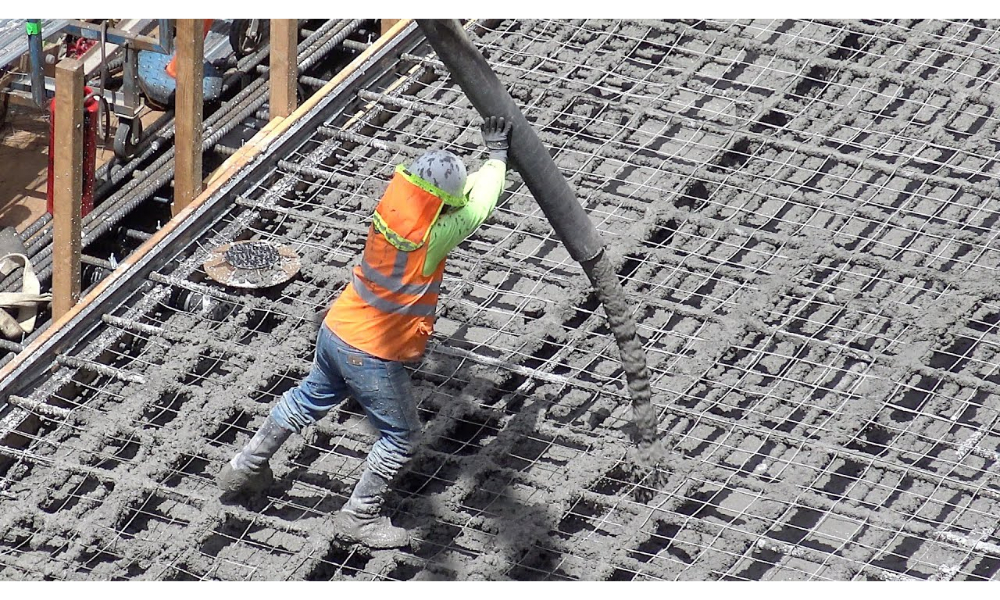

Concrete pumping is a technique used to transport and place liquid concrete from a truck-mounted pump to various locations on a construction site. Unlike traditional methods, where concrete is manually poured and spread, concrete pumping allows for the material to be pumped through hoses, directing it precisely where needed, regardless of the location or complexity of the site. This method uses specialized equipment, including pumps, hoses, and delivery systems, to streamline the process and ensure that concrete is delivered efficiently and safely.

Advantages of Concrete Pumping in Large-Scale Projects

1. Increased Efficiency and Speed

One of the most significant advantages of concrete pumping in commercial construction is its ability to increase efficiency and speed. Large-scale projects often require the rapid delivery of vast quantities of concrete, and traditional methods, such as wheelbarrows or cranes, can slow down the process. Concrete pumps, however, can deliver large volumes of concrete quickly and with minimal manual labor. This reduces the time spent on each pour, helping contractors stay on schedule and avoid costly delays.

2. Enhanced Precision and Control

In commercial construction, precision is crucial, especially when dealing with complex structures like multi-story buildings or intricate foundation designs. Concrete pumping allows for greater control over the placement of concrete, ensuring that the material is delivered exactly where it’s needed. This is particularly important in tight spaces or areas that are difficult to access, such as elevated floors or areas surrounded by other construction equipment. By utilizing concrete pumps, contractors can ensure a more precise and consistent pour, reducing the risk of errors that could lead to costly repairs.

3. Improved Safety and Reduced Labor Costs

Safety is a top priority on construction sites, and concrete pumping contributes to a safer work environment. Traditional concrete placement methods require significant manual labor, which increases the risk of accidents and injuries. Concrete pumping, on the other hand, minimizes the need for workers to handle heavy materials manually. With the pump doing much of the work, construction teams can focus on other critical tasks, reducing the potential for injuries and improving overall safety on the job site. Additionally, the efficiency of concrete pumping reduces labor costs, as fewer workers are needed for the same volume of work.

4. Versatility for Complex Projects

Concrete pumping is especially valuable for large-scale projects that involve unique architectural designs or difficult-to-reach areas. High-rise buildings, bridges, and foundations with complex geometries benefit from the flexibility offered by concrete pumping. The ability to pump concrete vertically or horizontally over long distances allows contractors to work in spaces that might otherwise be challenging to access with traditional methods. This versatility is essential for handling the diverse needs of modern commercial construction projects.

Concrete Pumping in High-Rise and Infrastructure Projects

Concrete pumping has become an essential technique for high-rise buildings and large infrastructure projects. In tall buildings, concrete must be pumped to elevated floors, often at significant heights. The pump systems used in these projects are equipped with powerful engines that can push concrete through long hoses and pipelines, overcoming the challenges posed by vertical construction. For large infrastructure projects, such as bridges and tunnels, concrete pumping ensures that the material is delivered to hard-to-reach areas quickly and efficiently.

Environmental Considerations and Cost-Effectiveness

While concrete pumping offers numerous benefits in terms of speed and precision, it also plays a role in minimizing environmental impact. The reduction in manual labor and machinery usage helps lower emissions and energy consumption on construction sites. Additionally, the faster delivery of concrete reduces delays, contributing to lower overall project costs. With concrete pumps, contractors can optimize their resource use, ensuring a more sustainable and cost-effective construction process.

Conclusion

Concrete pumping has proven to be a game-changer for large-scale commercial construction projects. With its ability to increase efficiency, enhance precision, improve safety, and reduce labor costs, it has become an indispensable tool in modern construction. As commercial projects continue to grow in size and complexity, the role of concrete pumping will only become more critical, enabling contractors to meet the demands of today’s fast-paced construction environment. Whether constructing towering skyscrapers, expansive commercial complexes, or intricate infrastructure projects, concrete pumping remains at the forefront of construction innovation.